What is

Fire Fighting Foam?

Firefighting foam is a specialized fire suppression agent designed to extinguish fires fueled by flammable liquids such as gasoline, diesel, oil, and jet fuel. It works by forming a blanket or film over the fuel surface, separating the fire from the oxygen in the air and suppressing the release of flammable vapors. This suffocating effect, along with the cooling properties of the foam, helps to quickly extinguish and prevent the re-ignition of liquid fuel fires.

Firefighting foams are classified into different types based on their composition and intended use. Common types include:

- Aqueous Film-Forming Foam (AFFF): Forms a thin film over the fuel surface to suppress vapors and smother the fire.

- Alcohol-Resistant AFFF (AR-AFFF): Specifically designed to combat fires involving alcohol-based fuels.

Fluorine Free AR Synthetic: The foam is environmentally friendly (fluorine-free), suitable for fires involving polar solvents (AR).

Aqueous Film-Forming Foam (AFFF)

Highly effective on hydrocarbon fuels like gasoline and diesel. However, it may not be as effective against fires involving polar solvents (non-polar). AFFF are designed for rapid-fire knockdown by producing a thin aqueous film which helps to prevent the release of fuel vapors. The film-forming liquid drains separates oxygen from the fuel surface, extinguishes the fire, and prevents re-ignition. AFFF provides excellent penetrating and wetting qualities when used on class a fires. The water content of the foam provides a cooling effect.

Features:

- Suitable for use with either fresh or salt water.

- Suitable for use with fiberglass, polyethylene, or stainless steel

- Suitable for use with siliconized dry chemical extinguishing agents.

Alcohol-Resistant AFFF (AR-AFFF)

Alcohol-Resistant Aqueous Film-Forming Foam (AR-AFFF) is a type of fire fighting foam designed to extinguish fires involving both hydrocarbons (like gasoline and diesel) and polar solvents (like alcohols, ketones, and ethers). The key feature of AR-AFFF is its ability to form a protective film on the surface of the burning fuel, preventing the release of flammable vapors and effectively smothering the fire.

Features:

- Suitable for use on hydrocarbon or polar solvent type fuels.

- Suitable for use with carbon steel, fiberglass, polyethylene or stainless steel.

- Suitable for use with siliconized dry chemical extinguishing agents.

Specifications:

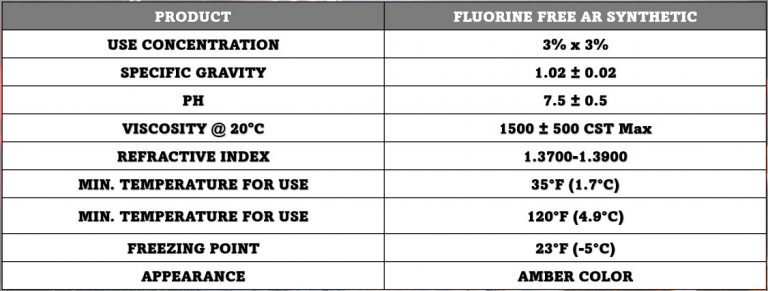

Fluorine Free AR Synthetic

The foam is environmentally friendly (fluorine-free), suitable for fires involving polar solvents (AR), and composed of synthetic materials for enhanced stability and performance. Create a foam blanket above the fuel on fire and add a cooling effect to rapidly extinguish the fire. It is an environmentally friendly foam that can be applied in low, medium, and high expansion.

Features:

- Can be used with fresh, brackish and sea water.

- Contains NO alcohols for higher flash point and compatibility with Class A/B Systems.

Specifications:

Foam System

Three components make up fire fighting foam. Foam concentrate, water, and air are present. These three materials combine to form a foam solution, which has a lower density than water, oil, or gasoline and is a stable mass of tiny, air-filled bubbles.

Due to this special mixture, the foam solution is extremely fluid and easily covers fuel surfaces by flowing over liquid surfaces. It can rapidly put out fires, cool burning fuels, and cool heated surfaces.

The water supply is linked to the pipe system through an autonomously operated Deluge Valve, which starts the water flow. Automatic detecting devices that are mounted alongside water spray nozzles are used to trigger automatic actuation.

How does it works?

- Fire-fighting foam agents put out a fire by severing it from the oxygen-rich air it needs to ignite. The most popular technique for foam system applications is balanced pressure proportioning. At the proportioner intake, the water pressure and foam concentrate pressure are matched, allowing the precise amount of foam concentrate to be metered into the water stream.

- An aspirating discharge device produces expanded foam by aspirating foam solution via an orifice, past air inlets, and into a mixing and expansion region.

- The foam solution doesn't mix with air in non-aspiration devices until after it has passed the discharge region and orifice.

How Firefighting Foam is Generated?

Foam concentrate is based on hydrocarbon surfactants. They have different compositions:

- Synthetic firefighting foams:

- Fluorine-Free Foams (F3, also known as FFF): creating a foam blanket full of bubbles

- Fluorinated foams: Aqueous Film Forming Foam (AFFF) and Alcohol-Resistant Aqueous Film Forming Foam (AR-AFFF also called AFFF-ARC)

- Protein-base foams:

- Protein foam

- Film Forming Fluoroprotein (FFFP)

- Alcohol-Resistant Film Forming Fluoroprotein (AR-FFFP)

The foam solution, also known as the premix solution, is a suitable combination of water and foam concentration. A 3% ratio indicates that three parts foam concentration is mixed with 97 parts water to make one hundred parts foam solution. At the nominal concentration, a foam concentrate is designed to be efficient. As a result, proper foam proportioning is critical for foam performance and effective fire extinguishment.

The foam solution is then expanded with air in the foam generator to generate finished foam. This ratio is determined by the type of foam concentration or fuel used. When a foam concentrate is specified as 1 x 3, it signifies that the concentrate-to-water ratio on a hydrocarbon fire must be 1%. On a polar solvent fire, 3 per cent.

The final foam is a collection of bubbles that create a stable foam blanket that separates the fuel supply from the oxygen supply. It extinguishes fires and stops the emission of flammable vapours. The volume of the completed foam created by the premix solution is represented by the expansion ratio. It may have a modest, medium, or large expansion. It has a strong relationship with foam generation equipment.

The AFFF foam blanket is made consisting of a thin aqueous coating that spreads quickly over the fuel surface, isolating the fuel from the oxygen supply. Alcohol resistant foams (AR-AFFF and AR-F3), on the other hand, generate a polymer layer to effectively extinguish Class B polar solvent fires. It keeps the fuels from destroying the foam. A long drainage period ensures an effective and long-lasting foam blanket. The drainage rate is determined by how long the foam blanket remains stable and protects more than 75% of the surface from burn back

How to Extinguish a Fire with Firefighting Foam?

Firefighting foam is ideal for fire suppression. It is made up of a premix solution (a mix of water and foam concentrate) and air. It condenses into a stable foam blanket that spreads over the fuels and sticks to the surfaces. Some foams generate a layer over the fuel surface that traps vapours. The application of fire fighting foam concentrate stops fuel from coming into touch with oxygen, resulting in the suppression of the fire. It also has a great cooling effect and will keep the fire from rekindling.

Firefighting foam works in two stages to suppress a fire:

- Separation effect: the foam blanket limits combustible evaporation by reducing oxygen access to the flammable substance.

- Cooling effect: it takes a lot of energy to turn the water in the foam blanket into vapour. This helps to minimise or eliminate the energy required by burning. This water vapour cools the fire’s high temperature and prevents thermal radiation from exacerbating the flames.

AITO specializes in cutting-edge fire protection systems and supply high-quality fire fighting foam. Trust our experience to safeguard your assets and ensure compliance with safety regulations. Please do not hesitate to call us for more details. Call us at 010-241 2534 / 03-831 4791 or email at [email protected]

The good news is AITO has capable technician that can possess the required abilities and information.