KITCHEN WET CHEMICAL SYSTEM

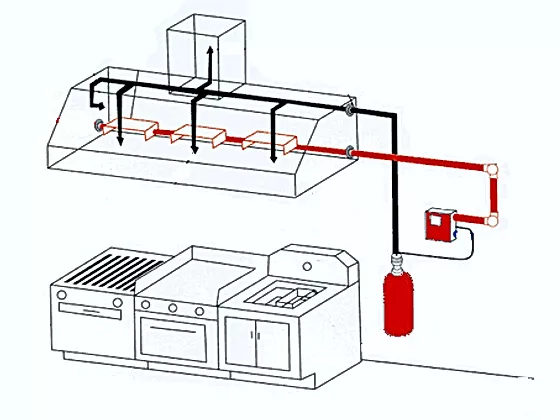

Wet chemical fire suppression systems are commonly used in restaurants and commercial kitchens to handle cooking fires caused by hot oil or grease. When a fire occurs, the system sprays fine droplets that quickly cool the grease, smother the flames, and lower the temperature to prevent the fire from reigniting.

Key Features

- Quick & Easy installation directly above high-risk cooking areas:

The flexible sensor tubing is easily installed directly inside the extractor hood – directly above cooking areas.. When in service, the tubing is pressurized with dry nitrogen to 16 bar. The dynamics of pressurization make the tubing more reactive to heat.

- Early fire detection:

- Instant suppression:

The sudden tube depressurization actuates the special pressure differential valve and instantly floods the cooking area with Class F extinguishing agent. The fire is quickly suppressed just moments after it began… minimizing damage and downtime.

Applications: Protection of

- Restaurant Hoods

- Plenums

- Filters

- Ducts

- Cooking appliances like deep fat fryers, range tops, upright broilers, rock char broilers, gas radiant char broilers and woks

AITO has a team of qualified engineers who possess the technical expertise and capabilities required for the role.